Beer recovery with reduced operating expenses.

As breweries face increasing pressure to deliver more with less, our centrifuges are perfectly positioned to maximize your beer recovery from every fermentation.

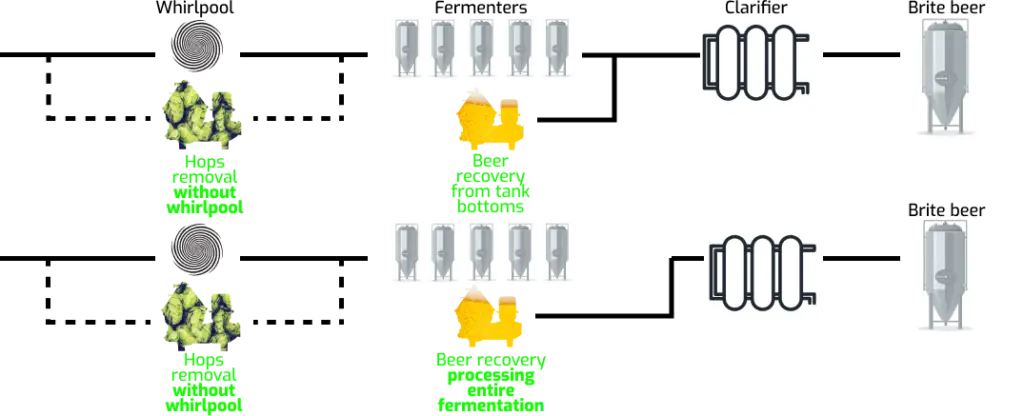

- Reduce losses by removing hops early, bypass or even eliminate the whirlpool.

- Maximize brew house use by running the full fermenter through our machine, including tank bottoms.

- Recover up to 5% more beer and get better equipment utilization.

Centrifuges in Beer Recovery: A Cost-Effective Brewing Solution

In the competitive world of brewing, every drop counts. Breweries are constantly seeking innovative ways to improve efficiency and reduce costs without compromising quality. One such solution is the use of centrifuges for beer recovery. This technology not only helps in maximizing yield but also enhances the overall brewing process.

Benefits of Using Centrifuges in Beer Recovery.

1. Maximize Yield

By recovering beer from the yeast and trub (the sediment formed during fermentation), breweries can reclaim a significant amount of liquid that would otherwise be wasted. This recovery can lead to an increase in overall production efficiency, allowing breweries to produce more beer without increasing raw material costs.

2. Cost Reduction

Every drop of beer recovered translates into reduced production costs. By minimizing waste and maximizing yield, breweries can lower their expenses on ingredients, water, and energy, ultimately improving the bottom line.

3. Improved Quality

Centrifuges can enhance the quality of the final product. By removing unwanted solids, breweries can achieve a clearer beer with a more stable shelf life. Additionally, the process helps in maintaining flavor profiles, as the yeast and sediment can often carry off-flavors.

4. Environmentally Friendly

Reducing waste is not only beneficial for the brewery’s finances but is also a step towards sustainability. By recovering and reusing beer, breweries can minimize their environmental impact, contributing to a more eco-friendly brewing process.

Conclusion

Centrifuges for beer recovery present an innovative solution for breweries looking to cut costs and improve efficiency. By maximizing yield, reducing waste, and enhancing product quality, this technology not only boosts profitability but also promotes sustainable brewing practices. As the brewing industry continues to evolve, incorporating centrifuge technology could be a game-changer for breweries of all sizes.

Call to Action

Interested in integrating centrifuge technology into your brewing process? Contact us today to learn more about our state-of-the-art centrifuges and how they can benefit your brewery!

Customer Testimonial: Coop Ale Works, Oaklahoma City.